Exploring the Advantages of Metal Powders for 3D Printing and Additive Manufacturing

The world of manufacturing is evolving at an unprecedented pace, with Metal Powders for 3D Printing and Additive Manufacturing leading the charge. This innovative approach to production not only streamlines the manufacturing process but also allows for the creation of complex and lightweight structures that were once deemed impossible. Among the myriad of materials used, Ti6Al4V powder, AlSi10Mg powder, and Additive Manufacturing Metal Powder stand out for their unique properties and advantages in various applications.

The Significance of Ti6Al4V Powder in Additive Manufacturing

Ti6Al4V powder is renowned for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, making it a preferred material for aerospace, medical, and automotive industries. The alloy is a blend of titanium, aluminum, and vanadium, customized to harness the best properties of each component. When utilized alsi10mg powder price in additive manufacturing, it facilitates the creation of durable, yet lightweight parts that meet the stringent requirements of high-performance sectors. Its ability to withstand extreme conditions without compromising on weight or durability makes it invaluable in advancing the capabilities of additive manufacturing technologies.

Read more about ti6al4v powder price here.

Read more about Additive Manufacturing Metal Powder here.

AlSi10Mg Powder: Revolutionizing Manufacturing with Versatility

The AlSi10Mg powder offers a different set of advantages, particularly known for its excellent castability, weldability, and high strength-to-weight ratio. This aluminum-silicon-magnesium alloy powder is predominantly used in automotive, aerospace, and industrial applications to produce parts with complex geometries and thin walls through additive manufacturing techniques. Its good thermal properties and ability to undergo post-processing treatments like heat treatment and surface finishing make AlSi10Mg a versatile choice for engineers and designers looking to push the boundaries of what’s possible.

Unleashing Potential with Additive Manufacturing Metal Powder

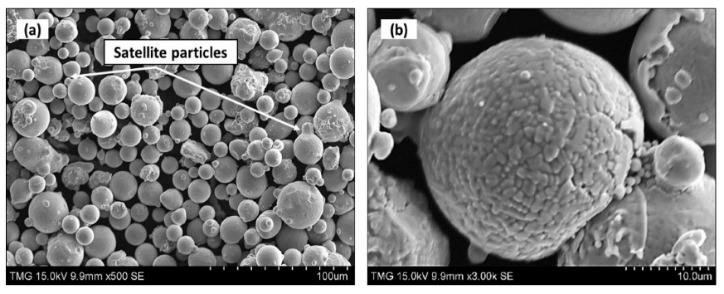

The term Additive Manufacturing Metal Powder encompasses a wide range of metallic materials designed for 3D printing applications. These powders are specifically engineered to have optimal particle size distribution, flowability, and packing density to ensure high-quality prints. The flexibility in choosing from a variety of metals — including stainless steel, nickel alloys, and cobalt chrome — allows for customization in mechanical properties to suit specific application needs. This adaptability is crucial in industries where customization and precision are paramount, paving the way for innovations in product design and functionality.

Conclusion

The use of Metal Powders for 3D Printing and Additive Manufacturing is revolutionizing the way we think about production and design. With advanced materials like Ti6Al4V powder, AlSi10Mg powder, and a broader range of Additive Manufacturing Metal Powder, the possibilities seem endless. These materials not only offer superior properties that can enhance product performance but also promote sustainability by reducing waste and energy consumption. As the technology continues to mature, we can expect to see even more innovative applications emerging, further transforming industries worldwide.

Leave a Reply